It's not just about ChatGPT: AI now moves, thinks, and acts in the physical world

The conversation around Artificial Intelligence

has changed. Until recently, AI was synonymous with complex algorithms, chatbots, or movie recommendations: something purely

software-based, living on screens and servers. But as Jensen Huang, CEO of NVIDIA, pointed out, today’s AI frontier

is no longer just about talking to a server, it’s about having devices that interact: true robots powered by intelligent

software.

Imagine getting into your car and, instead of just

seeing a warning light, asking what’s wrong and having it answer, explain the situation, and suggest a course of action.

Or a vehicle that, upon witnessing an accident, alerts other nearby vehicles. This is no longer science fiction: it’s

the age of Physical AI, Artificial Intelligence that transcends screens to invade the physical world, turning machines, devices,

and vehicles into cognitive entities.

In recent years, we’ve talked about voice

AI, chat AI, and video AI. Now this revolution is entering the tangible world. Today, according to Huang, “the next

wave of AI is Physical AI” [1]. In a recent speech, he stated that the automotive and robotics industries already operate

under the mindset that “anything that moves will eventually become autonomous” [2].

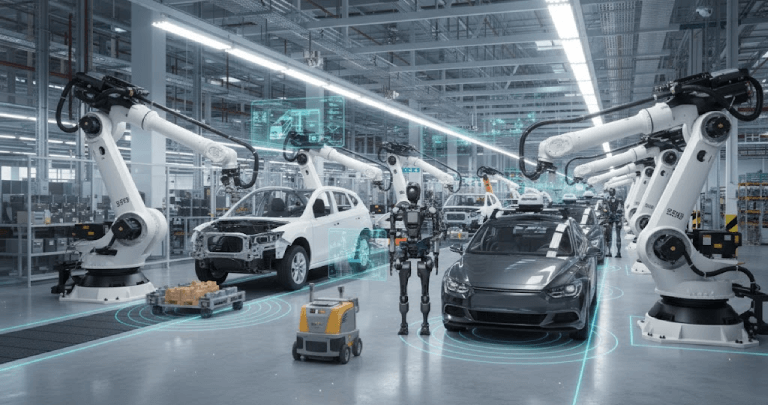

Machines as intelligent collaborators

The great shift

known as Physical AI is the inseparable and powerful union of hardware and software infused with Artificial Intelligence.

Think about the pain of an unexpected production line shutdown or the logistical inefficiency caused by failures detected

too late. Physical AI is the answer.

In Transport and

Logistics, cars and trucks don’t just drive themselves, they become intelligent agents. They monitor their own performance

(like the car that explains a dashboard warning) and communicate with other vehicles about accidents or road conditions, optimizing

routes and ensuring safety in real time.

In Manufacturing

and Industry 4.0, robots that once performed only repetitive tasks now use AI to adapt to new scenarios. They carry out quality

inspections with superhuman precision, dynamically adjust production, and work side by side with humans (cobots), increasing

efficiency and reducing errors [3]. Leaders like Aaron Parnas, Amazon’s robotics specialist, are driving this transformation,

integrating intelligent robots into large-scale logistics operations.

In Infrastructure

and Healthcare, autonomous drones inspect wind turbines and bridges, detecting faults before they become critical. Surgical

robots, assisted by AI, achieve micro-level precision, improving clinical outcomes.

Why Physical

AI is the next big thing

AI has always aimed

for autonomy, but now that autonomy has a body. What we’ve seen happen in the digital realm (the revolution of chat,

voice, and video powered by Generative AI) is now manifesting in everything that moves and interacts with the physical world.

At Visionnaire,

with over 29 years of experience in software development, we see Physical AI as the next leap in end-to-end process optimization.

Whether developing the intelligent software running in your equipment or creating a Digital Twin to simulate and train your future robots (as NVIDIA does with Omniverse), we are your ideal partner.

And for those working

in software factories, system integration, applied AI, or industrial automation, like Visionnaire, this is more than just

an interesting concept: it’s a strategic shift.

Until recently, AI was discussed as “pure

software”: training models, running them on servers, and delivering APIs. With Physical AI, hardware (sensors, actuators,

robots, vehicles), physical integration (mechanical, electrical), and embedded intelligence take the stage. In other words,

projects go beyond software alone. According to Huang, robotic systems require “three computers”: one for training,

one for simulation, and one to operate in the real world [4].

Companies that can unite AI software with reliable

hardware will be ahead. A McKinsey & Company article points out that software-defined hardware is becoming dominant and

will allow continuous updates without replacing the physical device [5]. For the market, this means smarter, more adaptable,

and longer-lasting products.

In sectors like automotive, logistics, and manufacturing,

where Physical AI is already in motion, the opportunity is enormous. As Forbes notes, supported by sensors, agents, and physical

networks, Physical AI transforms devices into autonomous entities acting in the real world [6]. And industrial automation

is one of Visionnaire’s core specialties.

Don’t wait for your competitors to turn their

machinery into autonomous robot teams. The time to embed intelligence into your physical world is now. Talk

to our specialists and discover how software and AI

can make your equipment work more intelligently, efficiently, and autonomously.

[1] “The next frontier of AI is physical AI.”: Nvidia CEO